Aircraft maintenance procedures in the past often depended on scattered paper-based processes and separate digital systems. This led to safety and compliance issues that posed risks to efficiency and regulatory compliance requirements. Our blockchain AI integration solution transformed traditional maintenance workflows by implementing a secure, automated system that eliminated manual transcription errors and ensured complete audit trail compliance throughout the maintenance lifecycle.

Project Overview

Traditional Challenges

Aircraft maintenance procedures in the past often depended on scattered paper-based processes and separate digital systems. This led to safety and compliance issues that posed risks to efficiency and regulatory compliance requirements.

Commercial airplane maintenance is known to be highly focused on documentation and safety in today's industries. Aviation companies need to keep records of all parts and procedures over years while following strict regulations set by organizations such as the FAA and EASA, along with national aviation authorities.

Data Fragmentation Issues

Fragmented data and loss of information posed a challenge in maintenance operations. Vital records were spread across incompatible systems leading to potential blind spots in critical maintenance history accessibility. This was due to:

- •Shifts and changes among technicians

- •System downtimes causing disruption in data retrieval

- •Risk of misplacing paper records

- •Hindered ability to conduct thorough analysis on component failure trends

Transcription Errors

Workflows that rely on paper involve data entry stages that lead to a 2 to 4 percent error rate in maintenance records. These mistakes tend to spread across systems leading to:

- •Inaccuracies in maintenance schedules

- •Procurement of parts issues

- •Compliance reporting problems

- •Incorrect compliance issues being flagged

Planning and Workflow Effectiveness Issues

Due to a lack of insight into maintenance progress at sites and a mostly manual approach to optimizing schedules:

- •Maintenance slots were left unused

- •Aircraft remained grounded unnecessarily

- •Resource assignment decisions were based on outdated data

- •Inability to predict maintenance needs due to absence of comprehensive historical data

Blockchain AI System Implementation

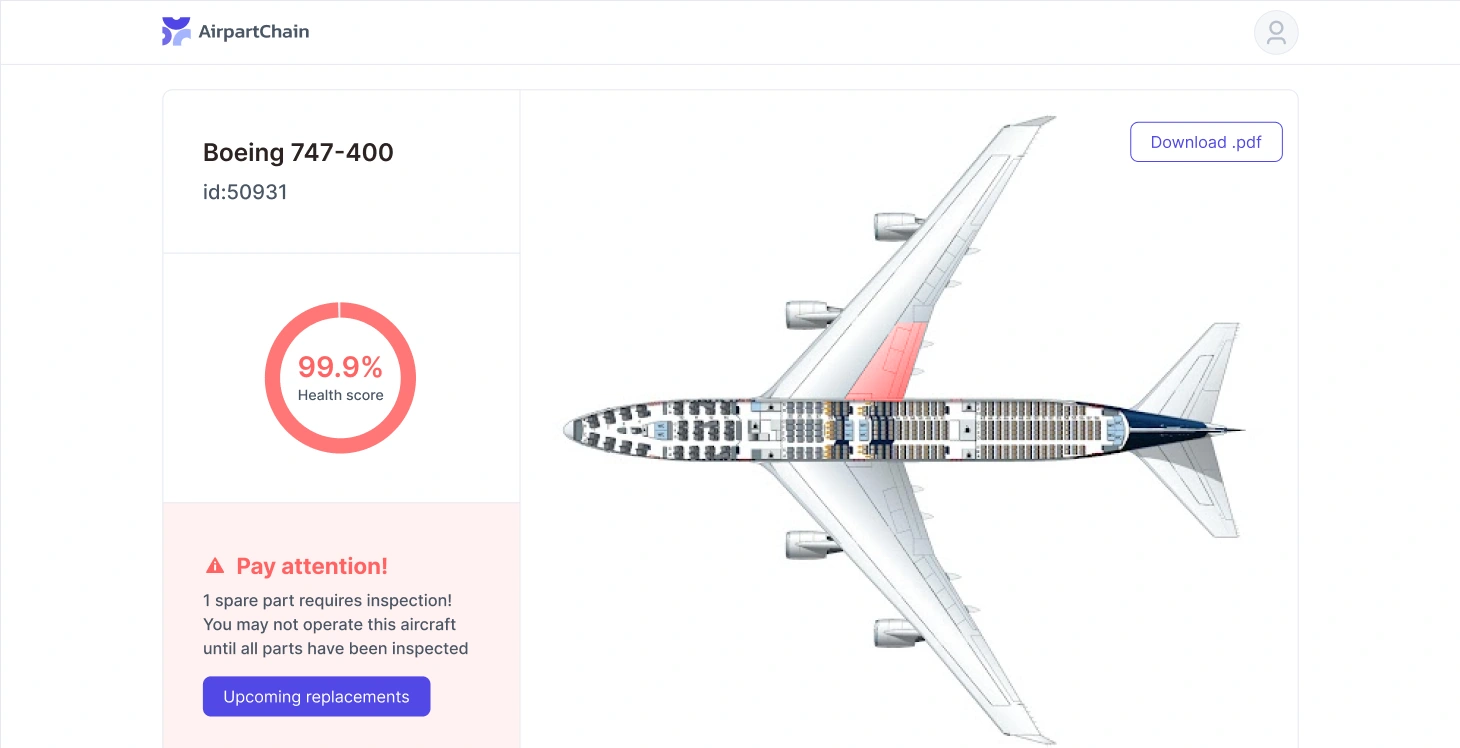

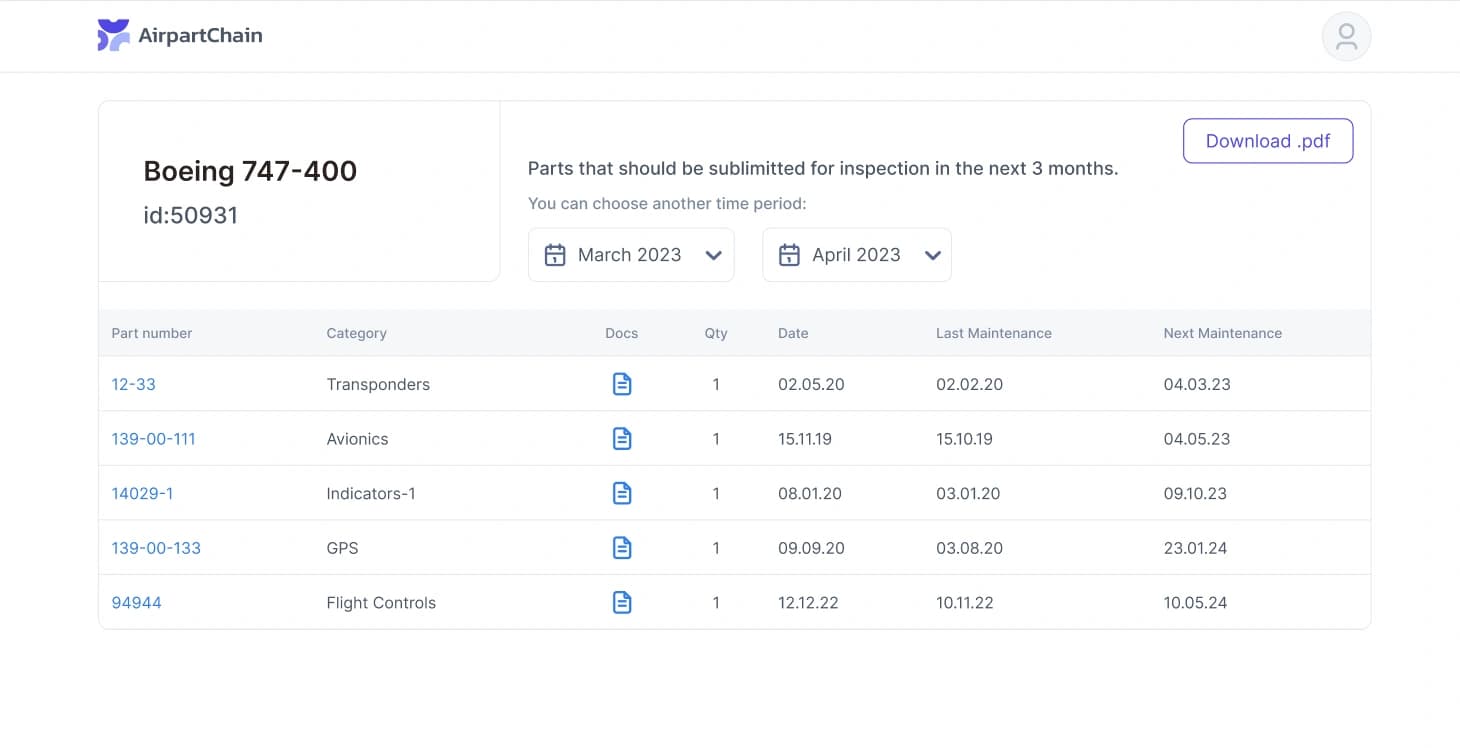

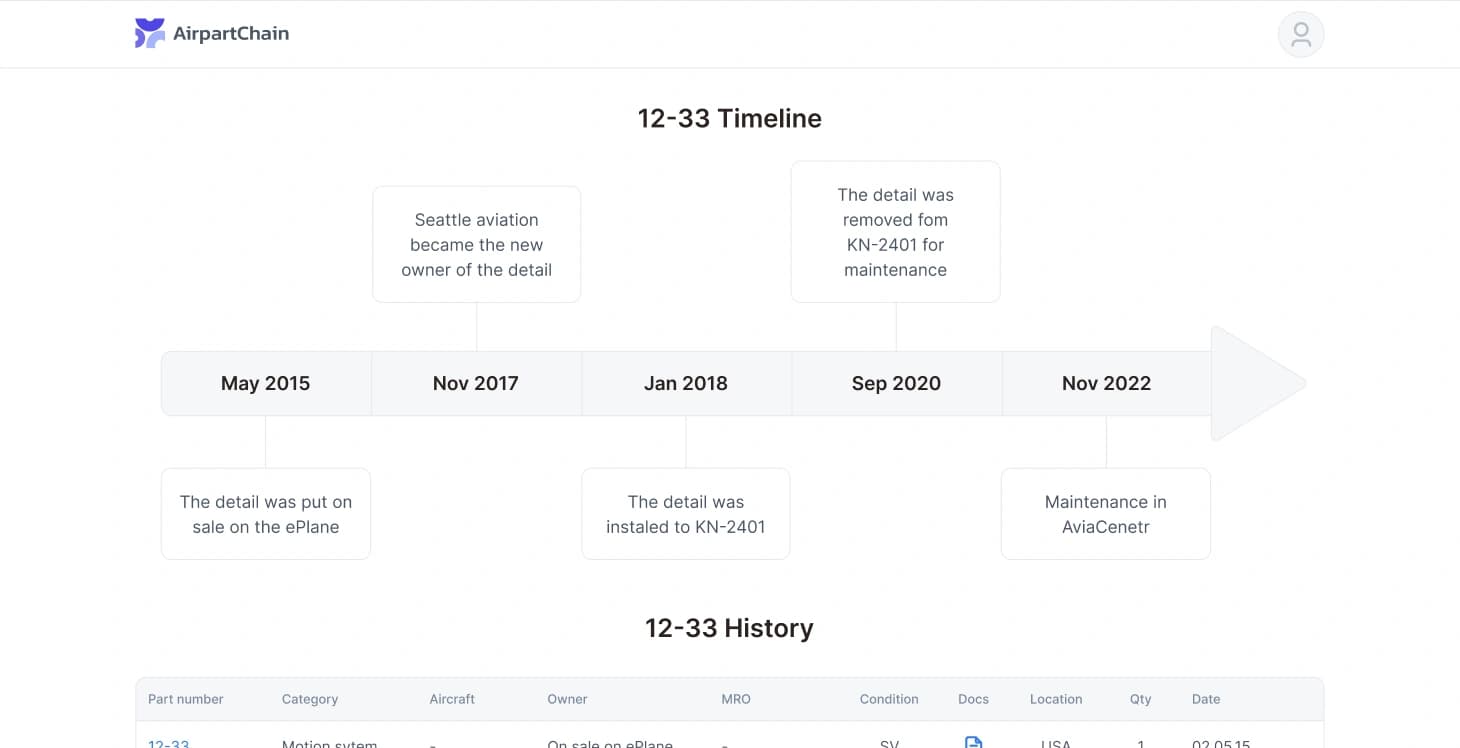

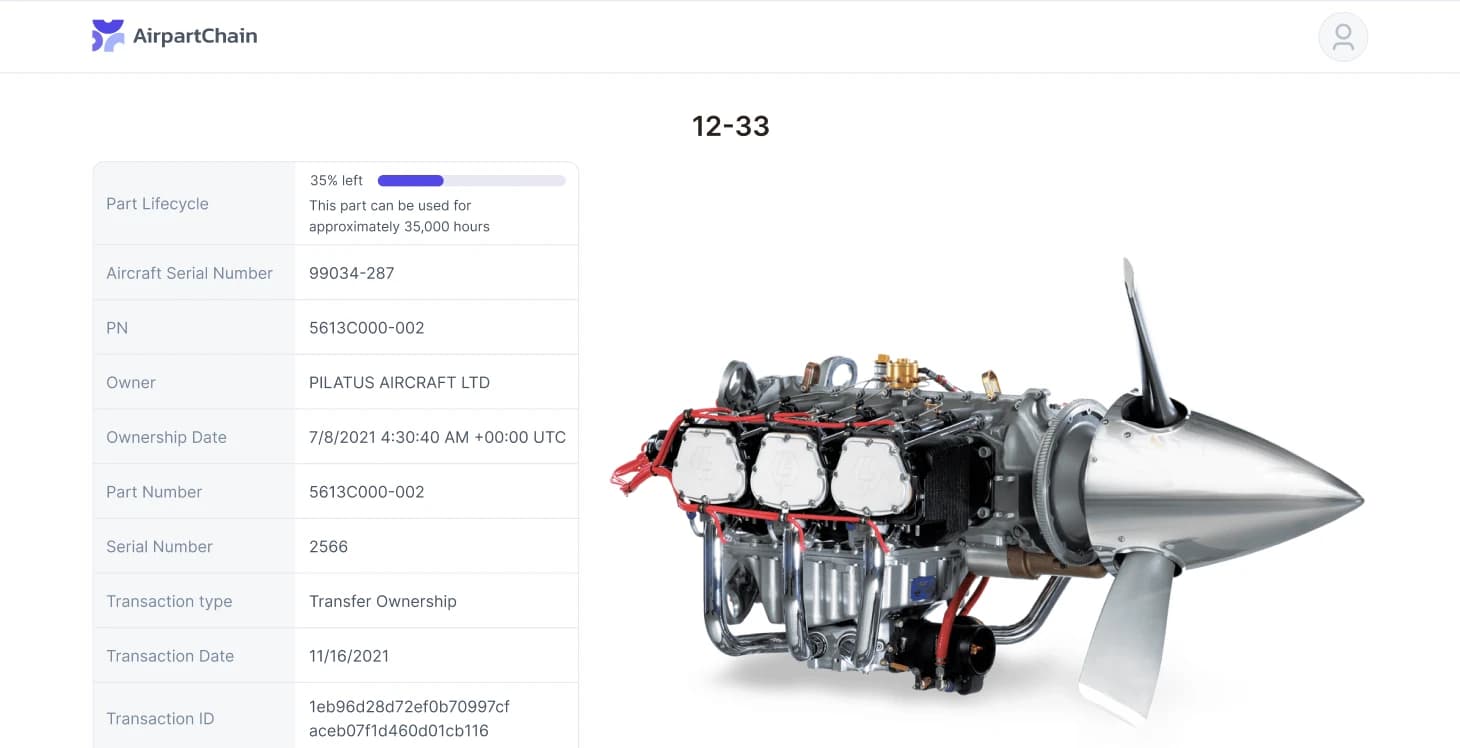

The integration of a blockchain AI system for maintenance tracking documentation processes removed manual transcription errors and ensured secure audit trails throughout the maintenance lifecycle. This enterprise blockchain solution provided the foundation for automated compliance and enhanced data integrity.

The use of time analytics led to a 34% decrease in unscheduled maintenance events while automated compliance reporting cut down regulatory audit preparation time from weeks to hours.

System Performance

System Performance

The system maintained an availability rate of 99.97% ensuring transactions were finalized within two seconds and handling more than 50K maintenance events every month across maintenance centers.

The overall expenses dropped by 28% thanks to:

- •Decreased administrative task load

- •Better optimization of parts inventory

- •Avoiding penalty costs related to compliance issues

Technical Architecture

Hybrid Platform Design

The platform that integrates hybrid blockchain and AI technology created a single source of truth for all maintenance tasks. The system merged:

- •Distributed ledger technology for record keeping

- •Machine learning features for analysis

- •Streamlined workflows

Blockchain Infrastructure

The Hyperledger Fabric private blockchain network was set up in maintenance facilities located in multiple regions with:

- •Validator nodes managed by each facility

- •Failover features in place

- •Smart contracts for maintenance workflow business logic

- •Consensus mechanism requiring approval from maintenance supervisors

AI Monitoring System

The AI monitoring system utilizes machine learning to:

- •Analyze sensor data and past maintenance logs

- •Predict equipment failures

- •Enhance maintenance planning efficiency

- •Process natural language in maintenance notes

- •Detect unusual patterns signaling potential safety concerns

Security Measures

Comprehensive security audits were implemented throughout the system to ensure data integrity and regulatory compliance.

Security Implementation

| Security Layer | Implementation | Purpose |

|---|---|---|

| Access Control | Multi-factor authentication | Mandatory for all system access |

| Permissions | Role-based permissions | Ensure separation of duties |

| Encryption | Cryptographic keys and digital signatures | Protected by hardware security modules |

| Data Transmission | AES-256 encryption | Maintain data secrecy |

Implementation Phases

Phase 1: Infrastructure Setup (Months 1-3)

During this phase, we set up the fundamental elements:

- •Blockchain network in key maintenance facilities

- •Validator nodes with secure connections

- •Basic smart contracts for storing maintenance records

- •APIs for integration with maintenance management systems

- •Security testing and regulatory clearance

Phase 2: Core Workflows (Months 4-7)

We transitioned maintenance processes to the blockchain platform:

- •Scheduled inspections and component replacements

- •Automated compliance checks and alert systems

- •Tablet applications for maintenance personnel

- •Data governance protocols and backup measures

Phase 3: AI Integration (Months 8-11)

Implementation of the machine learning system:

- •Training models using historical maintenance data

- •Real-time analytics dashboards

- •Automated reporting functions

- •Sensor integration for ongoing monitoring

Phase 4: Optimization (Months 12-15)

Final tuning and enhancement phase:

- •AI model optimization using operational feedback

- •Enhanced capabilities for more component types

- •Workflow automation and intelligent scheduling

- •Full supply chain integration

Results and Benefits

Operational Safety Improvement

By addressing gaps in maintenance records and reducing transcription errors, we successfully removed safety blind spots. Enhanced data quality improved risk assessment accuracy and safety decision-making on site.

Efficiency Gains

The boost in efficiency was significant with a 12 percent increase in aircraft utilization thanks to:

- •Scheduling optimization

- •Unified maintenance visibility across facilities

- •34% reduction in unscheduled maintenance events

- •Minimized costly flight disruptions

Transform Your Maintenance Operations

Discover how blockchain AI can revolutionize your aircraft maintenance processes today.

Supply Chain Transparency

Supply Chain Transparency

Supply chain transparency was greatly enhanced through tracking of parts origins, which:

- •Mitigated risks associated with counterfeit components

- •Increased accountability among suppliers

- •Reduced emergency procurement expenses by 38%

Compliance Automation

Automating compliance reporting significantly reduced audit preparation time from 2-4 weeks to 2-4 hours. Immutable audit trails allow regulators quick access to maintenance histories and help in closing compliance gaps.

Implementation Challenges

Change Management

Initially met with resistance from maintenance technicians accustomed to paper-based workflows. Success required:

- •In-depth training sessions with hands-on experience

- •Demonstration of the new method's advantages

- •Gradual workflow transitions instead of abrupt changes

Data Quality Foundation

Extensive data cleansing efforts were necessary before AI functionalities could provide meaningful insights. This process extended the analytics implementation timeline by several months.

Legacy System Integration

Integration proved more challenging than expected due to maintenance management software lacking API features. This required:

- •Custom integration solutions

- •Substantial development work

- •Continuous maintenance efforts

Projects should allocate additional time and resources to address potential legacy system integration hurdles.

Performance Optimization

Performance Optimization

The system initially faced performance issues under high loads during peak maintenance times. Optimizations included:

- •Consensus parameter adjustments

- •Node configuration improvements

- •Effective transaction batching methods

- •Reliable offline functionality for areas with limited connectivity

Technical Specifications

Monitoring and Performance

- •Prometheus and Grafana for system performance monitoring

- •Hardware Security Modules (HSMs) for enhanced security

- •Practical Byzantine Fault Tolerance (PBFT) consensus mechanism

- •18-minute compliance report generation time

Integration Layer

The integration layer connected the blockchain platform with:

- •Enterprise resource planning systems using APIs

- •Inventory management applications

- •Scheduling applications

- •Message queues for high-volume data ingestion

- •Data transformation services for blockchain format consistency

Project Results

- 34% reduction in unscheduled maintenance events

- 28% reduction in overall maintenance expenses

- 99.97% system availability achieved

- 12% increase in aircraft utilization

- Audit preparation time reduced from weeks to hours

Key Performance Metrics

Unscheduled Events

Reduction in maintenance

Cost Savings

Overall expense reduction

System Availability

Uptime achieved

Aircraft Utilization

Increase in efficiency

Technologies Used

Conclusion

The blockchain-based maintenance tracking system produced significant enhancements in safety, efficiency, and cost control measures. The implementation exceeded initial estimates across various areas while maintaining strict regulatory standards for data integrity and audit trails.

The 28% reduction in overall expenses, combined with improved operational safety and regulatory compliance, demonstrates the transformative potential of blockchain AI integration in aircraft maintenance operations.